| |

|

February 2015

|

Printing a nozzle

|

|

Mark is currently printing a preliminary version of the 10k nozzle. Later he will make a time laps video.  Video Video

|

^ top

| July 2012 |

SPL welcomes Devis Tonon in it's team |

We welcome Devis Tonon as a new team member. He holds a PhD in Applied Physics Technical University of Eindhoven) and a MSc in Aerospace engineering (Polytechnic University of Turin). He has experience in aeroacoustics, thermoacoustics and fluid dynamics. He will be a great help for us solving the thermoacoustic issues in one of our engines. |

^ top

| Sept 2011 |

10 kN engine at full throttle, modification on test stand |

Short summary: The engine ran on Ethanol/LOX, O/F about 1.95, thrust nearly a metric ton and we got a (measured!) ISP of about 232s at a chamber pressure of 21 bar... which is quite a good number! We pushed the chamber pressure further, but ended up with a molten nozzle (for optimizing combustion, short burning times are sufficient... so we only use mild steel nozzles at this state of the tests). More below...

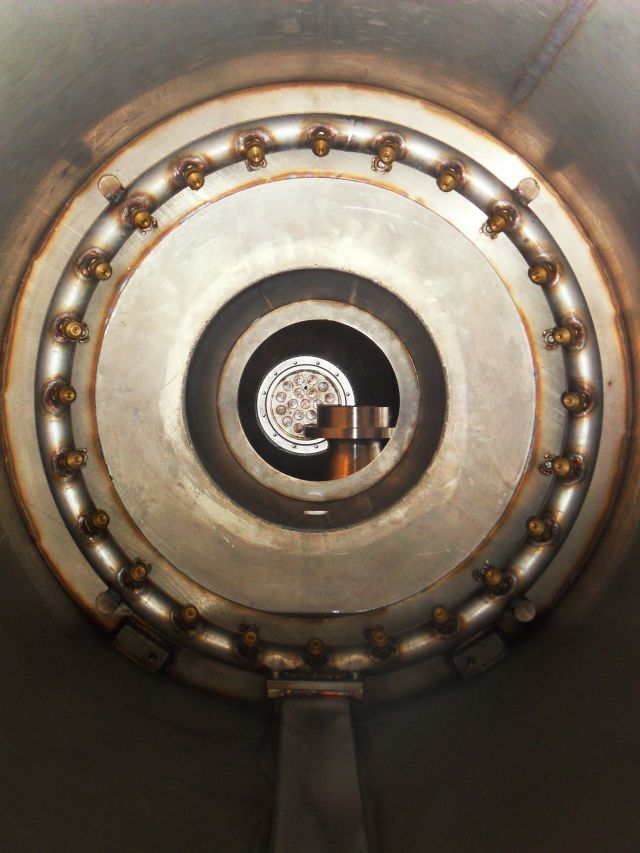

Some history: Some months ago we further modified our test stand to improve the sound suppression of the sound suppressing tunnel to be prepared to test the new 10 kN engine. For this we added a water injection ring into the movable tube in which we fire the engines. This cools the tube and reduces the noise level about 10 dBA:

|

|

(At the end of the tube you can see the injector with removed nozzle)

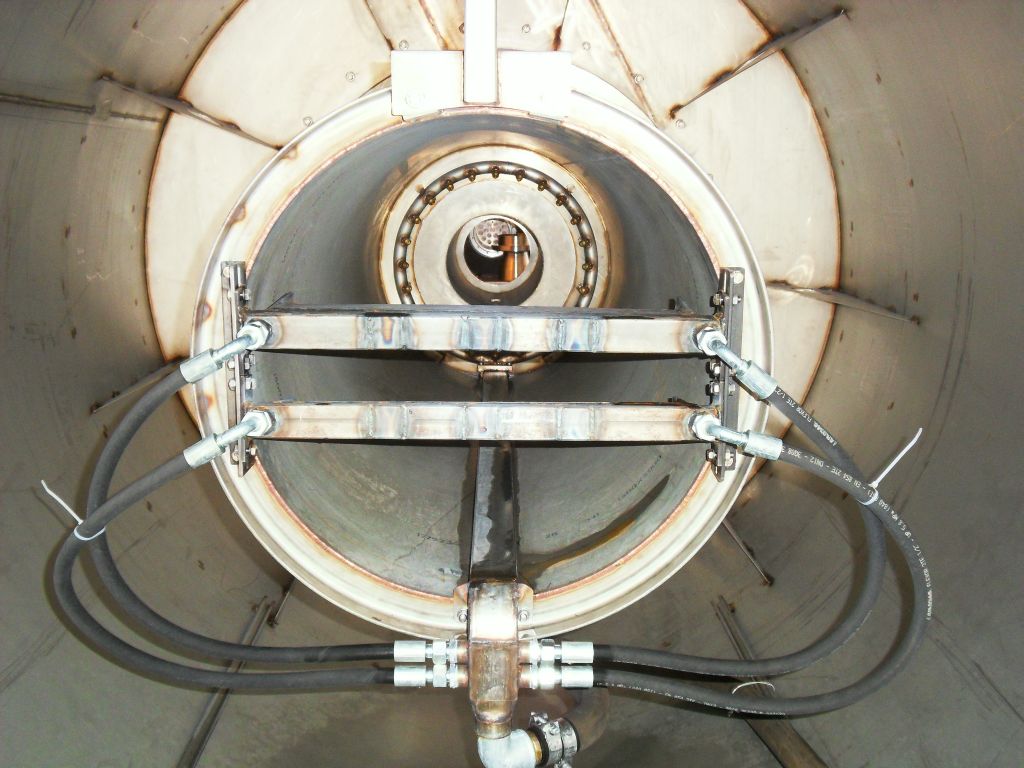

At the downstream end of the tube we additionally mounted a pair of water cooled wedges. They produce a shock in the supersonic exhaust, slowing down the gas speed to subsonic. This reduced the sound level for nearly 20 dBA!. Now we can fire our 10 kN engine even at night ;-) This was also used in the silos of US-ICBM's and is covered in several patents like US5422443.

Then we fired the engine the first time (The date in the movie is

wrong). Ignition happens at the time 15:40:30. In the upper right frame

you see starting the water injection into the tube prior ignition.

Video Video

We noticed a poor O/F of about 1.0 and found the source of the problem

in a collapsed LOX-Filter upstream of the LOX-main valve.

We removed it and fired the engine without it yesterday.

Video Video

We increased the chamber pressure further and further and finally hit

the limit what the steel nozzle can handle:  High speed video with 600

frames/s. High speed video with 600

frames/s.

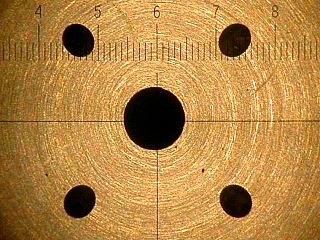

The nozzle showed some nice patterns of molten metal:

No damage to the rest of the engine or test stand. Only damage to the

engineers ego :-) We had a lot of fun yesterday! |

^ top

| May 2011 |

SPL tests 1 ton thrust rocket engine |

|

On

the 28 May, SPL run the one ton thrust liquid propelled rocket engine

(SLR 10k-I) for three times successfully.

We also tested our new

water cooling system, which reduces sound emissions and the temperature inside the sound absorber. The first tests

are part of a longer test programme of the SLR 10k-I. Have also a

look on our media page with press release and articles.

|

^ top

| April 2010 |

SPL meets Prof. Dr. Dr. Oliver Ullrich and Dana Simmet at UZH |

Isabell

Buttron and Adrian Mettauer, both PR & Marketing of SPL, got the

opportunity to visit the research laboratories of UZH's (University of

zurich's) Division of Space Biotechnology at Zurich-Irchel. There,

Prof. Dr. Dr. Oliver Ullrich, Adjunct Professor of Space Biotechnology

(UZH/University of Magdeburg) and Dipl.-Biol. Dana Simmet provided an

insight into their fascinating zero-g research.

After a tour

through the laboratories, where the effects of altered gravity forces

on cellular and molecular mechanisms are investigated, the SPL

associates received an introduction to the various scientific projects.

Amongst others, the scientists are performing experiments on board of

parabolic flights like with the Novaspace-owned Airbus A300 ZERO-G,

based at Bordaux/France. The aim of this research is to find solutions

to the various health-related problems astronauts are facing during and

after a mission under zero gravity conditions, such as a profound

decline in immune function, bone and muscle atrophy.

|

|

|

^ top

| 25.

January 2010 |

Mirage

III rocket engine was handed over to SPL |

|

SPL

bought a Swiss Mirage III SEPR rocket engine

from a private collector for a symbolic price.

It was handed over on the 15th January in La

Brévine (Jura). The engine had been developed

by the SEP (Société Européenne

de Propulsion) and was first tested in February

1962. It was used by the Mirage III as an additional

booster for tactical maneuvers like zoom climbs.

On the 15th of May 1963 a prepared French Mirage

III reached 26.06 km altitude and set an official

record for France, still standing today. Swiss

pilots flew the fully equipped Mirage III S

up to 24 kilometers until the 1980s. The Swiss

Air Force had used twenty engines from May 1969

to April 1990. They were license built by Hispano-Suiza

and had performed 2'170 rocket flights. SPL

has one of them, now.

The

liquid cooled engine could develop 15kN thrust

for nearly two minutes and could be re-ignited

in flight. It operated with nitric acid and

aircraft supplied kerosene. The ignition was

made with a hypergolic nitric acid TX2 combustion.

The chamber was fed by two centrifugal pumps

driven by an shaft coming from the aircraft

turbojet engine. The chamber is a saddle design

made of aluminum which can be completely disassembled

for maintenance. The chamber is cooled by the

nitric acid.

Records:

-

Holding the altitude record of France: 15.05.1963,

a Mirage III reached 26.06 km

-

most built aircraft rocket engine (275 built)

-

most used man-rated rocket engine (over 20'000

flights)

-

world record of manned rocket flights (over

20'000 flights)

-

world's most reusable rocket engine (average

of 35 flights between general overhaul)

-

round trip times < 15 minutes has been

demonstrated.

The

engine is a freshly refurbished one, just out

of the arsenal. We will not fire it again, but

we can learn a *lot* from its design and also

from the instructions for the operatinal ground

support. Most of it applies to the operations

of nowadays and intended rocket planes.

Two

AIAA Papers about the development:

The SEPR 844 Reusable liquid Rocket Engine for

Mirage Combat Aircraft, AIAA-90-1835

Reusable Man-Rated Rocket Engines, AIAA-43160-765

A

collection of pics when we inspected it

(some are from the museum in Le Bourget)

:

|

^ top

| 24. October

2009 |

Eugen Reichl, aerospace author, visited SPL |

|

Eugen

Reichl honored us with a visit of our facilities. He is a German

aerospace author and employee at the EADS Astrium. He published several

books and booklets, like the "Typenkompass; Bemannte Raumfahrzeuge;

seit 1960" (see all books on www.amazon.de). He also writes for the German space magazine "Raumfahrt Concret".

Have also a look on www.der-orion.com , the base-block of a multi-media spaceflight and astronomy portal operated by Maria-Pflug Hofmayr and Eugen Reichl.

|

^ top

| 23. September

2009 |

SwissCube - first Swiss satellite

successfully launched |

|

The first ever signals sent from a Swiss satellite

in space have been received in the Lausanne region. It’s a

unique moment for students, professors and of course the whole nation.

The satellite was successfully launched by the Indian PSLV-C14 this

morning (Swiss time). The first signals were heard at 12:20 from

California and the Netherlands. The Space Center Lausanne recognized

the call sign at 13:20 – so, all systems are running well.

SPL congratulates the SwissCube crew!

Related links:

|

^ top

| 9. Mai

2009 |

SPL, Talis Enterprise GmbH and the Space

Tourism Society - Malaysian Chapter (STS-MC) are signing a certificate

of cooperation |

|

The

certificate of

cooperation brings the skills and networks of SPL, Talis Enterprise

GmbH and STS-MC officially together. The goal is, to develop

sophisticated products for science or spacetourism purpose. The roles

are:

- SPL:

Propulsion components

- Talis

Enterprise GmbH:

Airframes, simulators; aerodynamic and thermodynamic skills

- STS-MC:

Merchandiser and

operator of products; worldwide connections especially to universities.

For

further details, please refer to the press release (only in German

available) from the 9th of Mai under the topic "Media"

|

^ top

| 3. December

2008 |

SPL gives lectures at the adult evening

classes |

|

Hans Ulrich Ammann, CEO SPL, and Adrian Mettauer,

PR & Marketing, hold a lecture at the Volkshochschule in Basel.

They presented the current state of all projects of SPL and gave a

brief view into the world of propulsion..

|

^ top

| September 2008 |

SPL meets project partners in

Malaysia |

|

Adrian Mettauer met the Space Tourism Society -

Malaysian Chapter (STS MC) in Malaysia. They run a roadshow for the

first Malaysian rocket plane, using an existing SPL rocket engine. It

will be a scaled version of a suborbital spaceplane and will be

controlled by remote. It is part of a research and

development programme, which is also related to the governments vision

2020 (being closer to industry nations in 2020). The purpose

of the plane is to test the SPL propulsion system in flight, the

trajectory for the suborbital spaceplane and the design. It will

be equipped with cameras and sensors. Its name is M-R2D2.

The goal of the roadshow was, to keep stakeholders informed and to

optain support from the government - which they got. Adrian Mettauer

and the STS-MC crew met the chief minister of Perak state (see

picture), the executive directors of the crown prince and executive

directors of the ATSB (Astronautic Technology). Adrian Mettauer also

hold a lecture at the Putra Malaysia University.

|

^ top

| 10. June 2008 |

SPL attends launch of TMA 12 in

Baikonur |

Hans

Ammann and his wife Monika visited Baikonur to attend the launch Soyus

TMA-12. They also met icons of the space history like Valentina Tereshkova (the fist

woman in space) and Sergei Krikalev (he holds the

record of total time spent in space: 803 days!). The pictures below can

be enlarged by clicking on them.

|

|

|

| Liftoff! |

Monika (on the right) with the first woman in

space, Valentina Vladimirovna Tereshkova

(on the left) |

|

|

|

Rollout

of the booster

|

Hans in

one of the assembly halls |

|

^ top

| 16. November

2007 |

Astronaut Nicollier visits SPL |

|

Dr. Claude Nicollier honored us with as visit of

our facilities. Claude Nicollier is the only Swiss ESA astronaut. As a

veteran of four space shuttle flights, Claude has logged more than 1000

hours in space. He flew as a mission specialist on STS-46 in 1992,

STS-61 in 1993, STS-75 in 1996 and STS-103 in December 1999. You can

read his CV here. Have a look at his homepage.

|

| 27. April 2007 |

SPL introduces its products and services |

|

We incorporated the portfolio of our products and

services in the web page. Have a look what we can do for you here.

We also added a media page with our appearance in the printed media and

TV.

|

| 21. February

2007 |

Staging mechanism designed for X-BOW I |

|

Our students at FHNW finished their work on the

stage separation mechanism for the X-Bow

I (which could also be used on AUSROC 2.5).

See also the news of 26. January 2007 and the

publications

area for their report. Thanks to Prof. U. Bopp and his students.

Other activities: In the time frame of the next 2 months we will test a

new 10 kN (~ 2000 lbs) engine. Project Enterprise is also progressing

fast. Stay tuned...

|

|

| An

animation of the mechanism. Click on the image to get a high resolution

animation |

A

closeup of the mechanism. Click on the image to get a high resolution

animation |

|

| 26. April 2006 |

SPL

on TV! |

- We

finally inaugurated our test cell and its corresponding equipment.

Everything works more or less perfect. We fired our 2.5 kN Engine

several times. Some impressions of a typical working day at SPL (4.1

Mb)

- The

official Swiss TV visited us and made a nice broadcast about our work

(commentary in German though):

|

|

Hot firing of the 2.5 kN engine. The engine is

still running in heat-sink mode. Next step will be a regenerative

cooled configuration as already tested in the late 2003

|

|

| 25. January 2006 |

Status

January 06 |

- The test

cell and it's corresponding equipment are finally finished. We will

fire in February :-)

- Two

student projects ended with their thesis work. One project was the

successor of the last year project "Designing and building of a stage

separation mechanism" and the other project was the "design of a gas

turbine to power turbo pumps":

|

|

| Turbine

rotor and stator row. It's a Curtis impulse turbine with a constant

pressure after the nozzle section. There is still lot of room for

optimization though... |

Turbine

test stand. You see the gas generator on the top, the water break on

the left. |

|

| 10. December 2004 |

Various

projects in progress

|

- Project

Enterprise. We recently started the project ENTERPRISE with

our partner Talis-Institut (sorry, you will

see nothing if Javascript is disabled). Just go to the Talis webpage

and choose the link to the Project Enterprise (sorry, no permalink on

the site) and our report in the september edition of the Talis online

magazine T.I.M.

(A local copy of our article: as a HTMLor

PDF document, both in German)

- Current

student projects:

- Construction

of a test bench for small turbines. The goal of this student

project at FHBB was the design, building and testing of a test bench

where modified turbines of automotive turbo chargers can be tested as a

power plant for turbo pumps. Our long term intention is a small low

cost turbo pump for small rocket engines. The reports can be found on

our publication page

- Designing and building of a stage

separation mechanism. The students worked out several

variants for a stage separation mechanism which can be used on rockets

with a diameter of 300 mm like X-Bow I or AUSROC 2.5. It can also be

used to deploy recovery equipment. The

reports can be found on our publication

page

- Our

encapsulated test cell is now ready for use. It cost us more

than two years of hard work. This is one of the reasons for the rare

news updates. Have also a look at the live weather data here.

|

|

|

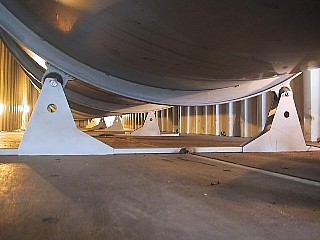

| The

orange container houses the sound absorbing device. The grey container

with the fan is the actual test cell. In the background the control

room which contains the data aquisition. |

The

rocket engine to be tested is built up on the table of the test bench.

It fires into an extension tubus of the absorber tunnel.

The test bench is bolted to a concrete block which is in turn connected

to a 30 tons foundation plate.

The total mass of the test stand cell and the sound absorbing tunnel

amounts to more than 100 tons!

The current development status permits testing engines with a thrust of

up to 30 kN.

By prolongation of the sound absorbing

tunnel and a slight upgrade of the test bench the range can be enlarged

to approx. 120 kN. |

|

|

|

| 23. March 2004 |

SPL

files its first Patent |

Device for Pressurizing

Propellant Tanks (Patent pending)

After a series of successful

prototype tests we filed our first patent application for a new Tridyne

pressurization system, with a wide commercial and military application

area. The patent has been lodged at the Swiss Federal Institute of Intellectual

Property at the 16th February. It is thought to be flown in ASRI's

AUSROC 2.5. A brief description

can be found here |

| 10. February 2004 |

Ongoing

work on the test cell and sound suppressing system |

| The work on the

encapsulated test cell and sound suppressing system set us back for

more than a year! Hopefully we can fire the next rocket engine inside

this new infrastructure in the timeframe of the upcoming 4 months. The

huge stainless muffler tube was mounted inside the 40 ft muffler

container. This container contains also water pumps for the water

curtain, filters, burst walls etc. The muffler tube will be surrounded

by sand. From the attached test cell we fire into the muffler tube, the water curtain inside the tube and a labyrinth

at the end will provide further noise reduction. See also the news from 19.

May 2003 |

|

|

|

| Peter

inserts the muffler tube into the 40 Ft container. |

The bolted down muffler tube. This is

necessary to prevent the tube from buoying upwards in the surrounding

sand bed. Vibrations absorbers insulate the tube from the walls of the

container. |

|

-

FHBB (University of applied science Basel) and

SPL continue their cooperation with two R&D projects:

|

|

| 22. Januray 2003 |

First

firing with the regenerativly cooled 2.5 kN LOX/Ethanol engine! |

Two

students of FHBB

(University of applied

science Basel), Gianni Ermini and Florian Kaiser, finished their

diploma thesis, made in the frame of a research program at SPL and

presented the results in a public exhibition. The focus of their work

was on designing, building and testing of a regenerative cooled

combustion chamber with 2.5 kN/560 lbs thrust (see also the news entry

of 10th November 01).

The students have analysed the heat flux through the chamber walls and

the heat transfer into the coolant (water, kerosene and pure ethanol) .

They have also developed a code to optimise the size and shape of the

cooling channels. Following a low cost approach, the combustion chamber

was made of aluminium. Their diploma thesis can be downloaded here (german!).

In the meantime we at SPL upgraded the test stand, so it is now fully

operational for LOX/hydrocarbon with tank pressures up to 5 MPa.

Finally we successfully fired the chamber 28th December 2002. A

veritable firework for new year's eve and we hope a god omen for the

New Year :-)

In an

ongoing partnership of SPL with FHBB it was decided, that a next step

will be the design of a small, low cost turbopump. The project starts

with a radial inflow turbine derived from a automotive turbo charger.

SPL thanks FHBB, Prof.

Dr. Peter von Böckh and the two students for the

great teamwork! A more detailed description of the engine and tests can

be found here.

|

|

|

| Parts of the combustion chamber. The chamber is

designed to be fully demountable to test various configurations. This

is also important to inspect the liner and its cooling channels after

test runs. Click on the image to enlarge... |

The inner liner with the milled cooling channels.

One of the two halves of the throat closeout has been removed. The

closeout mates very precisely with the liner to prevent any bypass flow

in the throat area. The temperatures in the cooling channels are

measured by thermocouples of 0.5mm diameter that are mounted through

small openings in the outer shell and in the closeout.

A second version of the liner has been machined with more cooling

channels. This will reduce the pressure drop, but results in a lower

velocity in the cooling channels and therefore in a lower heat transfer

as the mass flow of coolant remains the same. Click on the image to

enlarge ... |

|

|

|

Ignition!

The picture shows a test run under rel. low chamber pressure (o.6 MPa)

using LOX/ethanol at an O/F of 1.3. In this test, the injector was

equipped with only 3 injector elements (see 1st

September 02 and 11th

March 02) . Tests with full chamber pressure of 2.5 MPa will

be conducted as soon as we have finished the muffler system.

4 min hires

Realmedia movie of the event (7.3 Mb) .

4 min lowres Realmedia movie

of the event (2.6 Mb) .

|

An

overview of the test setup. One can clearly see the frozen LOX line and

LOX valve, the regen. chamber with it's feeding lines, the torch

igniter and several thermocouples. The LOX tank is on the top left. |

|

| 1. September 2002 |

Completion

of the LOX/HC engine and test stand in sight |

It seems that our work on the test

stand and the cryogenic equipment to test the 4 kN LOX/HC engine are

coming to a important milestone: The first firing of a LOX/HC engine

with an noteworthy thrust level. This is also a requirement for the

thesis work of our students at FHBB (see also the news entry from 10. November 2001)l. The next

news entry will hopefully show you a complete test setting or even a

working LOX engine :-)

|

|

|

| The torch igniter (see also news entry from 3. March

2001) fires through the injector plate of the heavy walled 4

kN LOX/HC engine. On the left: the attached copper case of the torch

igniter with the spark plug.A more detailed view of the injector plate

can be found here. |

The LOX-valve as designated on the test stand. The

assembly will be insulated, the extended shaft and actuator will be

heated to prevent them from icing. |

|

| 13. April 2002 |

Latest

firing of the 12 kN TETHIS I Solid Motor |

Saturday

the 13. April, we finished the solid propulsion program with a firing

of the 12 kN TETHIS I motor. The solid program is suspended now, so we

can concentrate our efforts to the liquid biprop development. More

information's (mainly the development of the TETHIS I motor and of

igniters) can be found on the project pages soon. The firing was done

with a configuration of two different propellant compositions:

30 ms

after pressing the red button, the motor delivered full thrust of 12

kN. The new MagTef igniter has done a good job! Virtually no pressure

peaks occurred. No smoking around for half a second like often seen in

HPR rocketry!

|

|

|

| The motor under full thrust of 12 kN. Peak thrust

was a bit more than expected, the thrust test stand jumped 3 cm (Note:

The thrust test stand is bolted to a concrete block of 2.5 metric

tons!). Click on the image to start a movie 800 kB, needs the latest Real-Player) |

Test stand and motor after firing. More infos about

the test stand can be found here

and here. |

|

|

| One of the grain segments. The grain close to the

igniter contains 0.6% CATOCENE burning rate catalyst to improve the

ignitability and to give an initial boost during liftoff. |

We also

tested a new type of igniter made of sintered Magnesium/Teflon used in

the actual test. After only 30 ms (!) the motor reached its full thrust

of 12'000 N without any pressure peaks. |

|

| 11. March 2002 |

Injector

for the heavy walled liquid propellant engine ready |

We have

finished the injector of the heavy-walled modular combustion chamber

(see also the news from 27. July 01

and 18.

October 99). The modular concept of the injector allows

various configurations.

|

|

|

| The injector plate with the inserted injector

elements. The element in the center is a Pentad surrounded by six

Triplet injector elements. The elements are made of a

Copper/Chromium/Zirconium alloy. |

A look through a microscope on the central Pentad.

The holes were made by a special deep-hole drilling process to get very

smooth holes and a perfect alignment. Note also the sharp edges and the

absence of any burr. The piece is showed as drilled, no additional

treatment was made. |

|

|

| One of the injector elements. The modular design

allows different configurations during the test phase. The final

injector will be a monolithic design made of aluminum. |

A special flow turbine will measure the LOX flow on

the test stand. A magnetical pickup counts the revolutions. |

|

| 10. November 2001 |

Cooperation

between SPL and FHBB goes on with the development of copper combustion

chamber |

|

23.

April 1999 SPL and FHBB (University of

applied science Basel) have concluded their future cooperation. In the

past semesters FHBB has analyzed the behaviour of various

injection-systems in a high-pressure environment (see also the news

entries 23.

April 99, 16.

November 1999, 26.

November 2000 and 23.

January 2001).

Today, we concluded a further partnership to design, build and test a

regeneratively cooled combustion chamber. The students will analyze the

heat flux through the chamber walls and the heat transfer into the

coolant. They will also optimize the size and shape of the cooling

channels. The combustion chamber will consist of a inner copper liner

with machined cooling channels and an outer shell of electro plated

nickel. We are very proud of gaining this partnership!

|

|

|

| A

rendering of the inner copper liner of the X-Bow I engine. At the

ground of the cooling channels, the wall's thickness is only about 0.8

mm to get the best heat transfer into the cooling fluid and to minimize

thermal stress |

The

combustion chamber consists of an inner copper liner with machined

cooling channels and an outer shell of electro plated nickel.

The picture shows a detail of a sample cutted out of of the electro

plated combustion chamber wall. |

|

Note: This will be the last news entry until

February 2002 because of the webmasters trip to Australia. Among other

things, he will also participate in the 11th

conference of the Australian Space Research Institute ASRI

(see also the presentation

we gave there).

|

| 14. September 2001 |

SPL is

visiting NERO launch campaign in the Netherlands |

NERO

has organized a launch campaign at ASK (an artillery test area of the

dutch army). SPL took the chance to see all the "northern lights" we

only knew from their web pages, mailing list etc. till then. Thanks

guys, that was a great day!

|

|

|

| |

The picture shows a rocket powered by a KN/Sorbitol

motor. It was build by the belgium amateur group VRO.

The start was perfect but the recovery system failed :-( |

The SSRV-1 (Small Scale Research Vehicle

1) build and flown by the danish group DSC.

The motor was also a "Candy"-Motor. The rocket also had a video

downlink. The above picture was taken from the DSC

home page with their permission. |

|

| 13. April 2001 |

First

shot on the new test stand with a hot water motor |

To consecrate our new test

stand, we mounted a hot water rocket motor on the test table.

This motor is a remnant from a former project (JATO). The vessel is

rated up to 6 MPa by national vessel authorities. Special thanks to Mr.

André Hool who made the motor available to us.

|

|

|

| The test stand mounted on a concrete block of 2.5

metric tons. In front the regulator for the 3 x3 kW heating cartridges.

Close to the nozzle one can see the security valves and the pilot valve

for the nozzle's internal valve. |

A view into the nozzle (20 mm diameter) with its

integrated valve. |

|

|

|

| Hansueli Ammann just pushed the red button. All the

equipment is certified by the national authorities, so it shouldn't be

dangerous standing beside of it. |

The Thrust curve at a hot water/steam pressure of 4

MPa. The peak at the beginning is the result of sloshing water during

opening the nozzle's valve. |

|

^ top

|

|

|